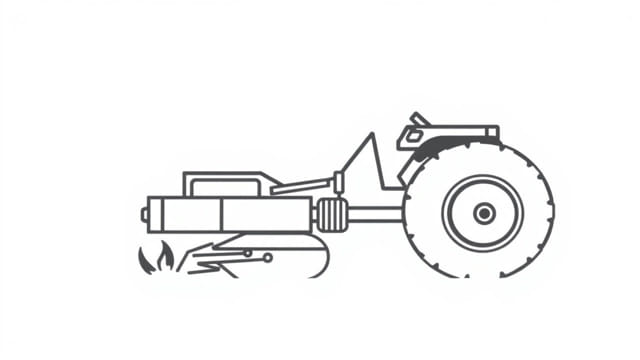

In agricultural machinery, the Power Take-Off (PTO) shaft is a critical component that transfers mechanical power from a tractor to an attached implement. One such implement is the Bush Hog, a popular type of rotary cutter used for mowing large fields, clearing brush, and maintaining pastures. The Bush Hog PTO shaft is essential in making this equipment function effectively. Whether you’re a seasoned farmer or new to land management, understanding how the PTO shaft works, its components, and how to maintain it properly can make a significant difference in both performance and safety.

What Is a Bush Hog PTO Shaft?

Basic Definition and Purpose

A Bush Hog PTO shaft is a mechanical drive shaft that connects the tractor’s PTO system to the Bush Hog rotary cutter. When the tractor’s PTO is engaged, the shaft rotates, delivering the necessary torque and speed to power the blades on the rotary cutter. Without a functioning PTO shaft, the Bush Hog would not operate.

Why It Matters

The PTO shaft plays a pivotal role in the efficiency and safety of mowing operations. An improperly functioning or incompatible PTO shaft can lead to mechanical failure or accidents. Choosing the right shaft, ensuring proper installation, and performing regular maintenance are all crucial steps in maximizing the lifespan of the equipment.

Key Components of a PTO Shaft

1. Yokes

The yokes are located at both ends of the shaft. One end connects to the tractor’s PTO output, while the other connects to the Bush Hog gearbox. These ends must be securely attached using locking pins or quick-release mechanisms to avoid disconnection during operation.

2. Telescoping Tubes

Most PTO shafts consist of two interlocking tubes that allow for length adjustment. This is important for accommodating different tractor-implement distances while maintaining a snug fit for efficient power transfer.

3. Universal Joints (U-Joints)

These flexible joints allow the shaft to operate at various angles without losing torque. They are key to adapting to the relative motion between the tractor and Bush Hog as they move over uneven terrain.

4. Guard Shields

Plastic or metal shields cover the shaft to protect the operator from rotating parts. These guards are critical for safety and must be in place at all times during operation.

5. Safety Chains

Chains are sometimes used to prevent the shaft guards from rotating along with the shaft, keeping them stationary for added safety.

Types of PTO Shafts for Bush Hogs

Not all PTO shafts are created equal. Different Bush Hog models may require different shaft types depending on power ratings, tractor specifications, and operational angles.

- Category 1: Suitable for smaller tractors and light-duty Bush Hogs.

- Category 2: Designed for mid-sized tractors with moderate horsepower.

- Category 3: Built for heavy-duty applications and high-horsepower tractors.

It’s essential to check your Bush Hog manual or consult with the manufacturer to ensure compatibility when selecting or replacing a PTO shaft.

Common PTO Shaft Problems and Solutions

Excessive Vibration

If the shaft vibrates during operation, it may be out of balance or misaligned. Check for bent tubes, damaged U-joints, or improper angles and correct them immediately.

Sticking or Hard to Connect

Rust, dirt, or wear can cause the telescoping sections to stick. Lubricate all moving parts regularly and clean the shaft before storage.

Guard Damage or Loss

Never operate a Bush Hog without intact shaft guards. Replace broken or missing guards to ensure safety.

Noise or Clunking Sounds

This may indicate worn-out U-joints or loose yoke connections. Inspect and replace damaged components as needed.

Maintenance Tips for Long-Term Performance

Regular Lubrication

Grease the U-joints and telescoping sections as recommended by the manufacturer. This prevents friction and extends the life of the shaft.

Inspection Before Each Use

Always check for visible damage, loose connections, or missing safety features before operating the Bush Hog. Address issues immediately to prevent further damage.

Store in a Dry Place

Moisture leads to rust and corrosion. After use, clean the shaft and store it indoors or in a covered location.

Replace Worn Parts

Components like U-joints, yokes, and guards are replaceable. Keep spare parts on hand to minimize downtime during the season.

Installation Guidelines

Measure Correctly

The shaft length must match the distance between the PTO output and the Bush Hog gearbox. If the shaft is too long, it can bottom out and damage the driveline. If too short, it may disconnect during operation.

Secure Connections

Use locking pins or quick couplers to fasten both ends securely. Shake the shaft lightly to ensure it’s locked in place before starting the tractor.

Angle Management

Try to maintain a straight or shallow angle between the tractor and the Bush Hog. Sharp angles put stress on the U-joints and increase the risk of failure.

Signs You Need a New Bush Hog PTO Shaft

- Persistent noise or vibrations despite maintenance

- Severe rust or corrosion that compromises strength

- Broken or missing guard shields

- Worn or damaged splines on the yoke

- Frequent disconnection or improper fit

When replacing the shaft, ensure it matches the specifications of your tractor and Bush Hog. OEM parts are recommended, but compatible aftermarket options are available as well.

Safety Tips for Using a Bush Hog PTO Shaft

- Never step over or near a rotating PTO shaft.

- Ensure all guards are in place and working properly.

- Turn off the tractor and disengage the PTO before making adjustments.

- Use safety chains to prevent guard rotation.

- Train all operators on safe handling and emergency procedures.

The Bush Hog PTO shaft may seem like a small component, but it plays a vital role in the overall performance and safety of your rotary cutter. Understanding its structure, choosing the right type, performing regular maintenance, and following safety practices can extend the life of your equipment and ensure smooth operation. Whether you’re maintaining pastures, clearing thick brush, or mowing fields, a properly functioning PTO shaft ensures that your Bush Hog operates efficiently and safely, day after day.